In automotive diagnostics and data logging, a cable is your most critical link. A weak link means corrupted data, failed flashes, and costly downtime. In our company, we engineer OBD cables from the ground up for flawless signal transmission, superior durability, and absolute reliability in the most demanding environments—from the service bay to the racetrack.

Manufactured with Precision

10,000+

Mate/Demate Cycles

-40°C to 105°C

Operating Temperature

50+ lb

Pull Test Endurance

100%

Electrically Tested

What defines it's normal or Perfect

Most cables look the same from the outside. It’s the engineering inside that defines their performance and lifespan.

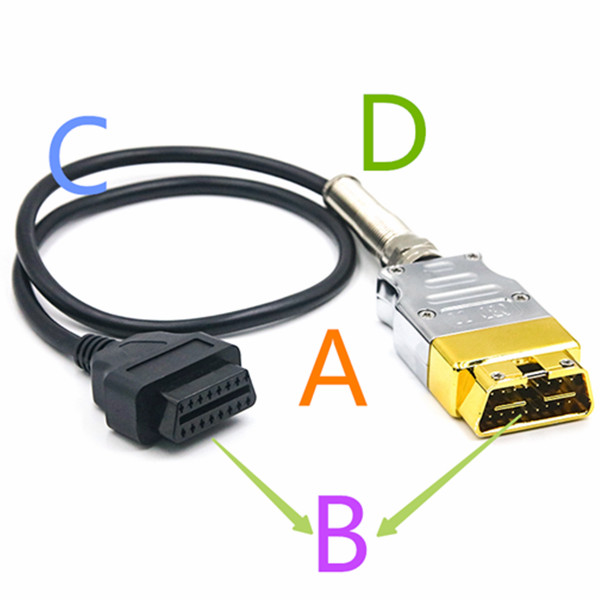

Precision-molded housing with ±0.05mm tolerance for a secure, click-fit connection that eliminates wiggle and intermittent faults.

Gold-flashed contacts over nickel plating for superior corrosion resistance and low electrical resistance, ensuring stable communication after thousands of insertions.

Dual-layer shielding: foil for high-frequency and braid for low-frequency interference rejection. This is critical for clean CAN bus data in electrically noisy vehicle environments.

Overmolded, flex-rated strain relief tested to 10,000+ bends. The connection point is the most common failure point; we’ve engineered it to be the strongest.

The right cable is the most critical, and most overlooked, piece of your toolkit. We engineer it to be the most reliable. While others focus on the lowest price, we focus on the highest performance. Here’s the engineering behind it.

3S Integrated Process Workflow

Define & Spec

We start with a technical consultation to understand your application’s voltage drop limits, data speed, environmental challenges, and connector interface needs.

Design & Prototype

Our engineers create a 3D model and schematic. We then build functional prototypes for your team to test and validate in your environment.

Validate & Approve

We don’t just wait for your feedback. We provide a full test report on the prototypes against the agreed specs, ensuring confidence before mass production.

Manufacture & Deliver

With approved samples, we move to our controlled production line, where every single cable undergoes a final electrical and functional test before shipment.

Why Choose Us

More Than a Supplier, We’re Your Engineering Partner

Automotive Expertise

We speak the language of the industry. Our team understands the stringent requirements of SAE, ISO, and OEM-specific standards. We design with the vehicle's environment in mind—from engine heat to road vibrations.

Proven Customization

We don't just offer customization as a service; it's our core business.

Bring us your most challenging interface problems, and we will develop a robust, reliable, and cost-effective solutions to you.

End-to-End Ownership

From initial concept and CAD modeling to tooling, production, and quality assurance, we manage the entire process. This ensures seamless integration, superior quality control, and a single point of accountability.

Speed & Agility

We understand your time-to-market pressures.

Our efficient processes and responsive communication are designed to get you from concept to finished product faster, without compromising on quality.

Don't see the perfect solution?

Let's build it together.

Your application is unique. Your connector should be too. Contact our engineering team today for a free, no-obligation consultation to discuss your specific requirements and how we can create the ideal OBD or automotive cables for you.